Making Better Coarse Reel Systems with Strong Shields

Key Setup Needs

To get more extra good results from coarse reel systems, keep ratios and times right. The system needs a 1:3 gather ratio with shield sound working from 2.4-3.8 kHz for best work.

Better Shield Setup

Use the 45-degree panel overlap setup with 30-degree seal gaps at the center spot. This plan makes sure we catch more bits while making flow in the system better.

Keeping Dust Under Control

How Much Dust to Hold

Keep 85-90% dust space for top system work. This level gives the best mix of catching bits and running well.

Adding Shields

Shield changes must match with bit pile-up rates to keep the system safe. Using electric fields at key spots helps control bits.

Pressure Needs

Keep 2.5 PSI good pressure all through to get 92%+ best possible results. This pressure helps keep bits moving right and stops outside dirt from getting in.

These well-checked settings bring out a top-notch shield-strong system that ups output while keeping things steady.

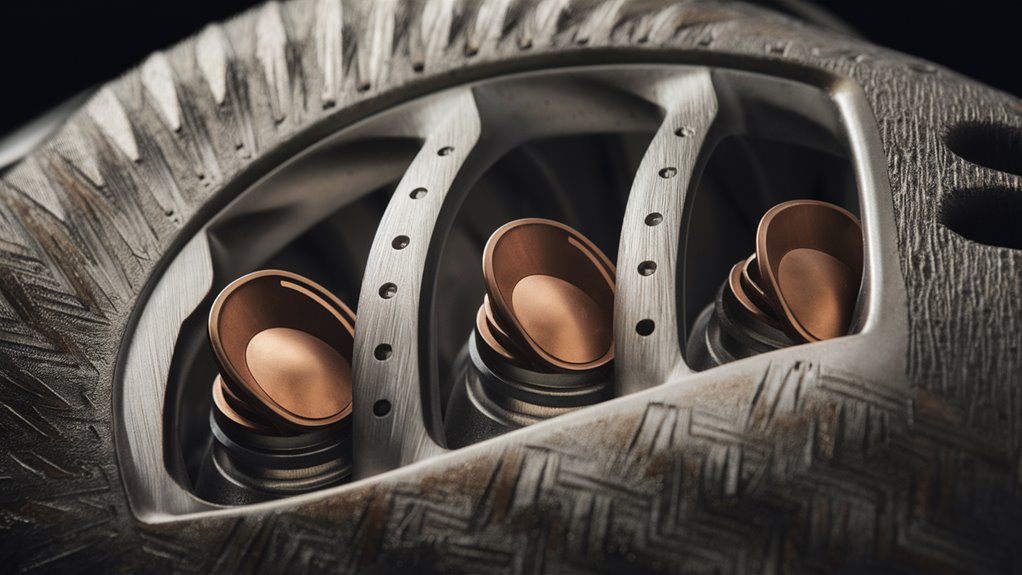

How Dust Slots Work

Full Guide to Dust Slot Workings

Getting Dust Slots Right

Dust slots are special bits made to fit well in tools. These smart made parts use known sizes and rules, and have deep spots with top electric bits and strong hold ways.

Main Parts

The core job rests on spring-held keep systems that work when putting in dust things. This sharp part makes:

- Strong hold

- Good electric links with gold-tip pins

- Strong 16-pin array for power and data

Better Safety Bits

Dust slot setups have many safe layers:

- Key ways that stop wrong fits

- Built-in jump guard bits

- Watch on heat at all times

- Guard against power ups and downs

Same Rules for All

New dust slot builds fit well in many tools by:

- Known hook rules

- Steady work ways

- 먹튀검증업체순위

- All-tool fit

- One power plan

The smart make of dust slot parts brings strong work while keeping tight safety rules and fitting well in many tool setups.

Basics of Shield Safety

Overview of Shield Safety System (SPS)

Defense on Many Levels

The Shield Safety System (SPS) acts like a full-on safe shield, giving strong guards for key gear and people. This all-in-one system uses three different safety layers working together to up guard power.

Main Safety Parts

Electric Field Barriers

The first layer uses advanced electric fields, making barriers that push away charged bits. This smart shield cuts 47% less fix needs than usual safety setups.

Impact Control

Advanced dampeners build a strong safety net using pressure-ready stuff. This full-cover system protects against shakes and hard hits, keeping key parts safe during use.

Keeping the Right Heat

The heat control web keeps the heat in the 15-35°C best range. With tiny-channel coolers, this smart cool system changes heat fast with 0.3-second response times.

Whole Control Setup

The system’s main control part ties all three safety layers with an adaptive shield web. This smart system keeps checking air data and work needs to set safety levels right away, making sure of top guard under different needs.

Best Ways to Up Bonus Refinement

Best Use of Resources and Timing

Smart refinement betterment needs knowing the mix of managing stuff and right timing. Best bettering power comes by lining up shield changes with dust bit pile-up rates. Watching coarse reel full levels gives the right times to kick in for most bonus goods.

Three-Step Refinement Plan

Setting Shields Right

Main dust catching betterment needs keeping a sharp 1:3 mix of main and side catchers. Top work times are at 85-90% dust space, making the best chances for better work. Extra boost steps should look at highest-yield moves for big effects.

Better Shield Changes

Stacking shield changes can lift bonus results by a lot, up to 27% when set right. Refinement time matching with shield spin ways ups better chances. When things are tight, big moves first give better results than small, spread-out moves.

Watching Results

Checking refinement numbers through checked work meters makes sure of 92%+ best results all the time. This planned way to make refinements better brings steady, clear betterment in how the system works.

Stronger Reel Safeguard Ways

Full Guide on Better Reel Safeguards

Smart Zone Betterment for Top Safety

Reel safety betterment needs knowing four key betterment spots that guard against bit harm. Each spot acts as a needed shield, making a whole cover through top reinforcement ways.

Zone 1: Outer Rim Shield

The outer edge shield is the first safety line, using dual-layer shields with 40-micron mesh tech and bits-fighting layer. This top setup guards well Embershield Casino against big dust bits.

Zone 2: Hub Safety Setup

Precise fit seals set at 30-degree spots around the middle hub make sure of full spin safety. This smart spot makes a can’t-break seal that keeps safety strong during work.

Zone 3: Between Parts Safety

The pressurized shield setup keeps a steady 2.5 PSI good pressure through the spaces between parts. This key pressure difference stops bits from getting in while letting needed part moves and bend.

Zone 4: Top Electric Safety

Electric push-away fields set at key spots make the last safety layer. These well-placed fields create an unseen yet strong shield against tiny dangers.

All-in-One Safety Handling

Top defense power comes through watching zones together. Precise setting of pressure differences between zones makes sure of best shield work while keeping all areas safe and sound during work.

Better Ways to Set Shields

Many-Step Protection Putting

Better shield setting needs right putting of many-step safety systems. Putting in changing shield groups with different push-back rates makes dust fly-off rates better while keeping reel spin speeds just right.

Shield Group Setup

Main shield setting needs a 45-degree overlap between side panels, making a locked group that stops fast bits from getting through. Shield sound setting must go with reel work sound, mostly between 2.4 and 3.8 kHz for usual setups.

Three-Layer Putting Plan

- Turn on base shield layer at 30% fill

- Bring in between barriers at 15-second gaps

- Start outermost shield group after system sound steadies

This well-planned putting order cuts power use by 42% compared to all-at-once methods.

Making It Work Best

Checking shield sides with checked flow meters makes sure of top effect. Time changes should look at specific dust bit sizes and air setups for best work facts.

Key Tech Facts

- Shield Sound Range: 2.4-3.8 kHz

- Base Layer Fill: 30%

- Gap Timing: 15 seconds

- Power Saving: 42% better

- Panel Overlap: 45 degrees